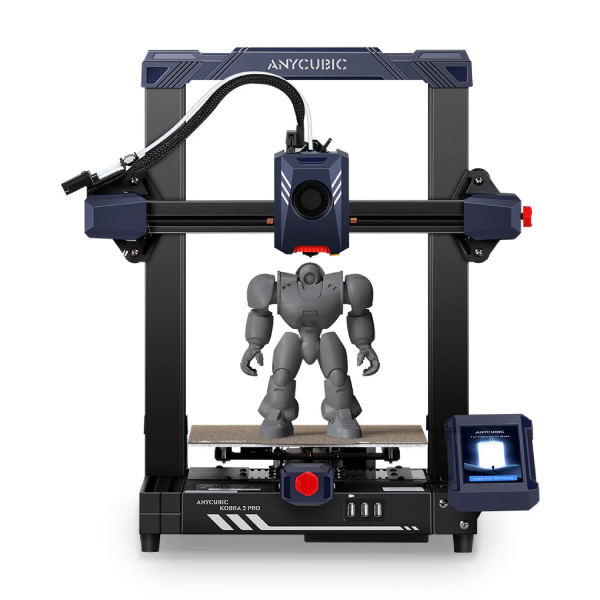

Anycubic Kobra 3 v2 Combo 3d printer

Why Anycubic Kobra 3 Combo ?

Anycubic Kobra 3 Combo aims to deliver an exciting and perfectly coordinated trio of 3D printing technologies to enhance your creative endeavors. Say goodbye to slow, dull, and tedious 3D printing!

This combo will elevate your 3D printing experience:

The Kobra 3 FDM 3D printer boasts an impressive printing speed of up to 600 mm/s and a maximum acceleration of 20,000 mm/s², quickly bringing your ideas to life. Supported by Anycubic Colour Engine Pro (ACE Pro), an automatic material system with a drying function, this printer from the renowned Kobra series is perfect for those interested in experimenting with multi-color printing.

- Smart Multi-Color Printing, Print in 4 to 8 Colors

- Print Fast, Seamlessly, Max 600mm/s

- ACE Pro: Dries while it Prints in Multi-Color

- Expansive Printing, 250x250x260mm

Anycubic Color Engine Pro (ACE Pro)

The Anycubic Color Engine Pro (ACE Pro) introduces a new level of convenience and reliability. It allows for simultaneous printing with two connected boxes, supporting up to 8 colors at once. The RFID recognition for Anycubic filaments ensures high-quality printing. ACE Pro has an active drying function to combat moisture-related issues, making it the only product on the market that combines active drying with multi-color printing capabilities. The intelligent side-drying feature keeps filaments dry during extended print sessions, lasting up to 24 hours for optimal printing conditions and flawless results. The anti-tangling protection design prevents filament tangling mishaps. The parallel connection of four discharge tubes allows for smooth color changes without the need to manually roll back filament inside the tubes. The intelligent color change function minimizes waste and speeds up the printing process.

Up to 600mm/s fast printing

With its impressive build volume of 250 x 250 x 260 mm, the Kobra 3 offers enough space for all your ambitious projects, while the print speed of up to 600 mm/s and an acceleration of 20,000 mm/s² enable breathtaking print times.

Robust design with integrated core modules

The printer impresses with its elegant design and at the same time impresses with its robust construction. The integrated, easy-to-install core modules have a sealed design that effectively protects the important components from dust and other influences.

Precisely manufactured XY axis

The printer's precision-engineered XY axis features a double metal core and SG15 bearings to ensure smooth and stable operation. The entire motion mechanism is incredibly wear-resistant, ensuring a long service life.

Stable Z-axis with dual leadscrews

The Z-axis of the Kobra 3 has a double-threaded rod, which ensures that the resistance is reduced during printing.

Improved cooling system

The design of the extruder fan has been optimized to easily achieve a higher operating speed of 7000 rpm. This allows heat to be dissipated better and the printed models to be cooled down faster.

Newly developed LeviQ 3.0 with an even more intelligent Z-offset

With LeviQ 3.0, automatic leveling becomes child's play. A specially developed module ensures intelligent compensation of the Z offset after automatic leveling, with the calculation and adjustment taking place fully automatically at the push of a button.

Smart functions for conducting self-tests

► Monitoring the belt tension: The resonance detection function allows the belt tension to be identified with a click and forwarded to a smart AI detection system. Attention! A camera must be used to use the AI function.

► Resume Printing function for automatic resumption of printing in the event of an unexpected power failure.

► Filament run-out sensor for automatic detection of running out filament.

Vibration compensation

An accelerometer sensor (G-sensor) for vibration compensation can be used to detect the resonance frequencies of the X and Y axes and to make adjustments to the motion control. Offset-printed lines are a thing of the past, and the precision and stability of your 3D-printed models are immediately noticeable.

Temperatures up to 300 °C

The Kobra 3 is designed for printing temperatures of up to 300 °C. The quick-release design allows the nozzles to be changed without tools.

More functions:

32-bit motherboard with silent driver for a quiet printing experience,

4.3-inch touchscreen with adjustable rotation angle (30°-60°),

Quick adjustment of the XY belt with a tensioner.

Anycubic Color Engine Pro – ACE Pro

With Anycubic's Color Engine Pro, you can print multiple materials simultaneously, create complex objects in colorful combinations, and save time and resources.

With 4 available spool slots, the automatic multicolor material system can accommodate up to 4 different colors at the same time to optimally support your multicolor printing. If the device is combined with another ACE system, even 8-color printing with a wide range of color combinations is possible.

How does multi-color printing work with Color Engine Pro?

The desired colors are automatically switched during the printing process according to your slice settings and the corresponding consumables are delivered to the printer. It's that easy!

Active drying function for more printing success

ACE Pro uses a dual 200-watt PTC heating element for active and even drying of your filaments during the printing process. The heating module is supported by two powerful fans that ensure hot air circulation. Tip: The interior temperature can be set up to 55 °C with optimal humidity.

Drying during printing or filament storage

The drying function can of course be used throughout the entire printing process to ensure that moisture-free filaments are always available. However, thanks to the Sealed Space Design, the Color Engine Pro can also be used for the safe and careful storage of filaments.

Anti-tangle design

The Anycubic Color Engine Pro is connected to the extruder in parallel through four output tubes. Since each of the filament slots has its own output tube, when changing colours, not all of the filament in the output tubes needs to be wound back to the spool, but only the part that is fed back into the inner chamber of the extruder. This reduces the possibility of spool entanglement on the one hand and prevents the material from running out in a moment on the other.

An active rewind function allows the device to actively rewind the filament during a color change. The combination of a parallel connection and active winding benefits the anti-tangling function.

Smart features:

► Clogging detection: A smart mechanical buffer structure detects blockages in good time and consequently interrupts the print.

► Automatic refilling of two consecutive color filament spools: After the first spool has been used up, printing of the second spool with the same color filament will automatically begin.

► Intelligent color change: A special algorithm calculates the color category of the printed model layer by layer. Adjacent layers are continuously printed with the same color, reducing material changes and filament waste. This also noticeably reduces the overall printing time of a model.

► RFID Sync: In-house filament spools equipped with an RFID chip are automatically recognized by the ACE regarding their colour and material type.

.png)

.png)

.png)